|

Application |

Finish planing |

|---|---|

|

Cutterhead’s Material |

steel |

|

Diameter |

100, 125, 150 mm |

|

Cutting Length |

50 – 305 mm |

|

Straight Bore |

30, 40, 50 mm. 1, 1 1/4, 1 1/2, 1 13/16 in |

|

Wings |

4 or 6 Wings |

| Knife Material | Tungsten carbide |

|

Cutting Angle |

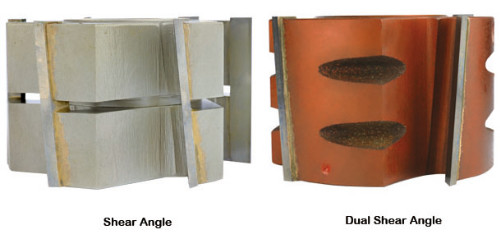

Straight, Shear Angle, Duel Shear Angle |

|

Applying Machine |

Four Side Moulder, Multi-Side Moulder, Spindle shaper, Copy Shaper |

|

Cutting Material |

Solid Wood, MDF, Plywood |

|

Dynamically Balanced |

6,000 or 8,000 rpm |

Information Of Production

About Brazed Planing Cutter (iron)

- Brazed Planing Cutters are our most reasonable cutterhead for finish planing, and used in Moulders, Copy Shapers and spindle shapers.

- The Brazed Planing Cutter (steel) can offer customized dimension. According to customers requiring like more cutting wings, shear cutting angle, harder knives etc.

- All the Brazed Planing cutters are dynamically balanced (6,000 or 8,000 rpm), preventing uneven vibration.

About Customzation

1. The Brazed Planing Cutterhead of steel body can customized Three kind of cutting angle, straight, shear angle, dual shear angle.

2. More cutting wings (4,6 and 8 wings) for finer surface.

3. According to wood material, we offer fit knives to enhance durability and efficiency.

Specification

|

Model |

Diameter (mm) |

Length (mm) |

Bore (mm) |

Wings |

|---|---|---|---|---|

|

A1ID125L 2d40W4 |

125 |

50 |

40 |

4 |

|

A1ID125L 3d40W4 |

125 |

75 |

40 |

4 |

|

A1ID125L 4d40W4 |

125 |

100 |

40 |

4 |

|

A1ID125L 5d40W4 |

125 |

125 |

40 |

4 |

|

A1ID125L 6d40W4 |

125 |

155 |

40 |

4 |

|

A1ID125L 7d40W4 |

125 |

180 |

40 |

4 |

|

A1ID125L 8d40W4 |

125 |

205 |

40 |

4 |

|

A1ID125L 9d40W4 |

125 |

230 |

40 |

4 |

|

A1ID125L 10d40W4 |

125 |

255 |

40 |

4 |

|

A1ID125L 11d40W4 |

125 |

280 |

40 |

4 |

|

A1ID125L 12d40W4 |

125 |

305 |

40 |

4 |

|

A1ID125L 2d50W4 |

125 |

50 |

50 |

4 |

|

A1ID125L 3d50W4 |

125 |

75 |

50 |

4 |

|

A1ID125L 4d50W4 |

125 |

100 |

50 |

4 |

|

A1ID125L 5d50W4 |

125 |

125 |

50 |

4 |

|

A1ID125L 6d50W4 |

125 |

155 |

50 |

4 |

|

A1ID125L 7d50W4 |

125 |

180 |

50 |

4 |

|

A1ID125L 8d50W4 |

125 |

205 |

50 |

4 |

|

A1ID125L 9d50W4 |

125 |

230 |

50 |

4 |

|

A1ID125L 10d50W4 |

125 |

255 |

50 |

4 |

|

A1ID125L 11d50W4 |

125 |

280 |

50 |

4 |

|

A1ID125L 12d50W4 |

125 |

305 |

50 |

4 |

|

A1ID125L 2d40W6 |

125 |

50 |

40 |

6 |

|

A1ID125L 3d40W6 |

125 |

75 |

40 |

6 |

|

A1ID125L 4d40W6 |

125 |

100 |

40 |

6 |

|

A1ID125L 5d40W6 |

125 |

125 |

40 |

6 |

|

A1ID125L 6d40W6 |

125 |

155 |

40 |

6 |

|

A1ID125L 7d40W6 |

125 |

180 |

40 |

6 |

|

A1ID125L 8d40W6 |

125 |

205 |

40 |

6 |

|

A1ID125L 9d40W6 |

125 |

230 |

40 |

6 |

|

A1ID125L 10d40W6 |

125 |

255 |

40 |

6 |

|

A1ID125L 11d40W6 |

125 |

280 |

40 |

6 |

|

A1ID125L 12d40W6 |

125 |

305 |

40 |

6 |

|

A1ID125L 2d50W6 |

125 |

50 |

50 |

6 |

|

A1ID125L 3d50W6 |

125 |

75 |

50 |

6 |

|

A1ID125L 4d50W6 |

125 |

100 |

50 |

6 |

|

A1ID125L 5d50W6 |

125 |

125 |

50 |

6 |

|

A1ID125L 6d50W6 |

125 |

155 |

50 |

6 |

|

A1ID125L 7d50W6 |

125 |

180 |

50 |

6 |

|

A1ID125L 8d50W6 |

125 |

205 |

50 |

6 |

|

A1ID125L 9d50W6 |

125 |

230 |

50 |

6 |

|

A1ID125L 10d50W6 |

125 |

255 |

50 |

6 |

|

A1ID125L 11d50W6 |

125 |

280 |

50 |

6 |

|

A1ID125L 12d50W6 |

125 |

305 |

50 |

6 |

|

Note: Can customize shear angle and dual shear angle. |

||||