|

Application

|

pre-planing or heavy cutting |

|---|---|

|

Cutterhead’s Material |

High Tensile Steel |

|

Diameter |

100, 125, 150 mm |

|

Cutting Length |

50 – 305 mm |

|

Straight Bore |

30, 40, 50 mm. 1 1/2, 1 13/16 in. |

|

Insert knife |

Square Tungsten Carbide Insert knife |

|

Insert knife size |

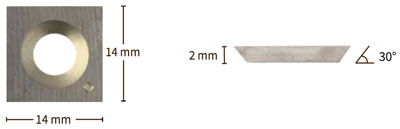

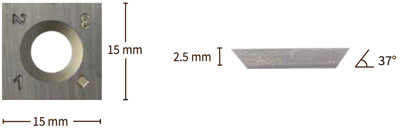

14 mm x 14 mm x 2.0 mm (30-degree bevel) 15 mm x 15 mm x 2.5 mm (37-degree bevel) |

|

Cutting Angle |

spiral angle |

|

Suitable Machine |

4 sides moulder, Spindle Shaper and Copy Sharper |

|

Cutting Material |

solid wood, MDF, plywood |

|

Dynamically balanced |

6,000 or 8,000 rpm |

Information of production

About Spiral Cutterhead

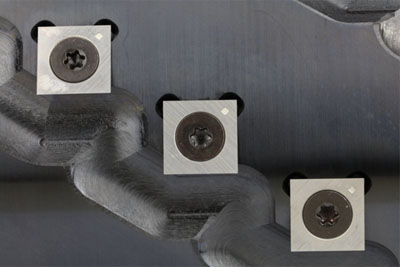

The Spiral Cutterheads are suitable for pre-planing having 3 main features, extremely High feeding speed, low noise and reducing tear out problem.

According to cutting material, LR-Tool offers two kinds of Spiral Cutterhead. One is Spiral Cutterhead for normal pre-planing, using 14 mm x 14 mm x 2.0 mm insert knives (30-degree bevel). The other is Spiral Cutterhead for heavy cutting, using 15 mm x 15 mm x 2.5 mm insert knives (37-degree bevel).

Spiral Cutterheads has a lot of advantage. To begin with LR-Tool’s special step grooves, it has astonishing chip-throwing ability to avoiding thrown chips hurt the workpiece’s surface. In addition, the noise level will drastically reduce by the step groove. Comparing with straight cutting angle, spiral cutting angle is a finer design. The cutting resistance will evenly distributed to many tiny square inserts that spirally arranged around the surface of cutterhead and continually cut the workpiece by each small point. This cutting way can remarkably reduce tear-out problem. Moreover, this lightly cutting method will diminish the load of bearing and spindle, extend the life span and reduce electric consumption. Moreover, upgrading to an aluminum body is also available. The Light-weighting body will lighten the load of bearing and spindle further .

The square insert knives are made by tungsten carbide, suitable for cutting solid wood and man-made material, MDF and plywood etc. Each square insert knife has four new edges and Each edge will surpass 10 times durable than High Speed Steel knife. If insert knife dulled, you don’t need sharpen the it immediately, just clean and turn all knives 90-degree and you may keep on working. Until all 4 edges run out. On the other hand, the necessary replacing insert knife is not only blunt, but damaged by hidden rock or nail. If a square insert nicked, just spend a small price to replace the nicked insert. Comparing with replacing a set of expensive straight knife, this design is economical.

Large chips always weaken the efficiency of dust collection equipment. Spiral cutterhead makes extremely tiny wood dust that can help dust collection’s efficiency.

Features

- The cutting resistance will be distributed to each small insert knife, continuously cutting workpieces by point by point. Thus, the Spiral-structure-design can substantially enhance feeding speed.

- LR-Tool’s special spiral step shape grooves have remarkably chip-throwing ability that can prevent workpice’s surface hurt by thrown chips. Moreover, the special grooves can significantly reduce noise.

- Placing knife work is easier. Just put the square insert into the knife spot and fit it with a screw. You don’t need to use any position tool.

- Smaller wooden sawdust makes dust collection more efficiency.

- The spiral cutterhead with 14 mm x 14 mm x 2.0 mm (30‐degree bevel) insert knives are suitable for normal pre‐planing.

- The spiral cutterhead with 15 mm x 15 mm x 2.5mm (37‐degree bevel) insert knives are suitable for heavy cutting. The bigger insert has better structure to dealing with heavy cutting need.

- If an insert nicked, you only spend a small price to replace it.

- Upgrading aluminum body is also available. The light‐weighting body lowers the load of motor and spindle, and reduce electric consumption.

Specification

Specification for Spiral Cutter Head (14 x 14 x 2.0° mm, 30 bevel)

|

Model |

Diameter (mm) |

Length (mm) |

Bore (mm) |

Wing |

|---|---|---|---|---|

|

A7D125L 2d40W6 |

125 |

50 |

40 |

6T |

|

A7D125L 3d40W6 |

125 |

75 |

40 |

6T |

|

A7D125L 4d40W6 |

125 |

100 |

40 |

6T |

|

A7D125L 5d40W6 |

125 |

125 |

40 |

6T |

|

A7D125L 6d40W6 |

125 |

155 |

40 |

6T |

|

A7D125L 7d40W6 |

125 |

180 |

40 |

6T |

|

A7D125L 8d40W6 |

125 |

205 |

40 |

6T |

|

A7D125L 9d40W6 |

125 |

230 |

40 |

6T |

|

A7D125L10d40W6 |

125 |

255 |

40 |

6T |

|

A7D125L11d40W6 |

125 |

280 |

40 |

6T |

|

A7D125L12d40W6 |

125 |

305 |

40 |

6T |

|

A7D125L 2d46W6 |

125 |

50 |

46 |

6T |

|

A7D125L 3d46W6 |

125 |

75 |

46 |

6T |

|

A7D125L 4d46W6 |

125 |

100 |

46 |

6T |

|

A7D125L 5d46W6 |

125 |

125 |

46 |

6T |

|

A7D125L 6d46W6 |

125 |

155 |

46 |

6T |

|

A7D125L 7d46W6 |

125 |

180 |

46 |

6T |

|

A7D125L 8d46W6 |

125 |

205 |

46 |

6T |

|

A7D125L 9d46W6 |

125 |

230 |

46 |

6T |

|

A7D125L10d46W6 |

125 |

255 |

46 |

6T |

|

A7D125L11d46W6 |

125 |

280 |

46 |

6T |

|

A7D125L12d46W6 |

125 |

305 |

46 |

6T |

|

A7D125L 2d50W6 |

125 |

50 |

50 |

6T |

|

A7D125L 3d50W6 |

125 |

75 |

50 |

6T |

|

A7D125L 4d50W6 |

125 |

100 |

50 |

6T |

|

A7D125L 5d50W6 |

125 |

125 |

50 |

6T |

|

A7D125L 6d50W6 |

125 |

155 |

50 |

6T |

|

A7D125L 7d50W6 |

125 |

180 |

50 |

6T |

|

A7D125L 8d50W6 |

125 |

205 |

50 |

6T |

|

A7D125L 9d50W6 |

125 |

230 |

50 |

6T |

|

A7D125L10d50W6 |

125 |

255 |

50 |

6T |

|

A7D125L11d50W6 |

125 |

280 |

50 |

6T |

|

A7D125L12d50W6 |

125 |

305 |

50 |

6T |

|

A7D125L 2d40W8 |

125 |

50 |

40 |

8T |

|

A7D125L 3d40W8 |

125 |

75 |

40 |

8T |

|

A7D125L 4d40W8 |

125 |

100 |

40 |

8T |

|

A7D125L 5d40W8 |

125 |

125 |

40 |

8T |

|

A7D125L 6d40W8 |

125 |

155 |

40 |

8T |

|

A7D125L 7d40W8 |

125 |

180 |

40 |

8T |

|

A7D125L 8d40W8 |

125 |

205 |

40 |

8T |

|

A7D125L 9d40W8 |

125 |

230 |

40 |

8T |

|

A7D125L10d40W8 |

125 |

255 |

40 |

8T |

|

A7D125L11d40W8 |

125 |

280 |

40 |

8T |

|

A7D125L12d40W8 |

125 |

305 |

40 |

8T |

|

A7D125L 2d46W8 |

125 |

50 |

46 |

8T |

|

A7D125L 3d46W8 |

125 |

75 |

46 |

8T |

|

A7D125L 4d46W8 |

125 |

100 |

46 |

8T |

|

A7D125L 5d46W8 |

125 |

125 |

46 |

8T |

|

A7D125L 6d46W8 |

125 |

155 |

46 |

8T |

|

A7D125L 7d46W8 |

125 |

180 |

46 |

8T |

|

A7D125L 8d46W8 |

125 |

205 |

46 |

8T |

|

A7D125L 9d46W8 |

125 |

230 |

46 |

8T |

|

A7D125L10d46W8 |

125 |

255 |

46 |

8T |

|

A7D125L11d46W8 |

125 |

280 |

46 |

8T |

|

A7D125L12d46W8 |

125 |

305 |

46 |

8T |

|

A7D125L 2d50W8 |

125 |

50 |

50 |

8T |

|

A7D125L 3d50W8 |

125 |

75 |

50 |

8T |

|

A7D125L 4d50W8 |

125 |

100 |

50 |

8T |

|

A7D125L 5d50W8 |

125 |

125 |

50 |

8T |

|

A7D125L 6d50W8 |

125 |

155 |

50 |

8T |

|

A7D125L 7d50W8 |

125 |

180 |

50 |

8T |

|

A7D125L 8d50W8 |

125 |

205 |

50 |

8T |

|

A7D125L 9d50W8 |

125 |

230 |

50 |

8T |

|

A7D125L10d50W8 |

125 |

255 |

50 |

8T |

|

A7D125L11d50W8 |

125 |

280 |

50 |

8T |

|

A7D125L12d50W8 |

125 |

305 |

50 |

8T |

|

A7D125L17d50W6 |

125 |

450 |

50 |

6T |

|

A7D125L18d50W6 |

125 |

460 |

50 |

6T |

|

A7D125L17d50W8 |

125 |

450 |

50 |

8T |

|

A7D125L18d50W8 |

125 |

460 |

50 |

8T |

|

A7D150L20d50W6 |

150 |

500 |

50 |

6T |

|

A7D150L20d50W6 |

150 |

610 |

50 |

6T |

|

A7D150L20d60W6 |

150 |

500 |

60 |

6T |

|

A7D150L20d60W6 |

150 |

610 |

60 |

6T |

|

A7D150L20d70W6 |

150 |

500 |

70 |

6T |

|

A7D150L20d70W6 |

150 |

610 |

70 |

6T |

|

A7D150L20d50W8 |

150 |

500 |

50 |

8T |

|

A7D150L20d50W8 |

150 |

610 |

50 |

8T |

|

A7D150L20d60W8 |

150 |

500 |

60 |

8T |

|

A7D150L20d60W8 |

150 |

610 |

60 |

8T |

|

A7D150L20d70W8 |

150 |

500 |

70 |

8T |

|

A7D150L20d70W8 |

150 |

610 |

70 |

8T |

|

A7D150L36d70W6 |

150 |

910 |

70 |

6T |

|

A7D150L36d80W6 |

150 |

910 |

80 |

6T |

|

A7D150L36d70W8 |

150 |

910 |

70 |

8T |

|

A7D150L36d80W8 |

150 |

910 |

80 |

8T |

|

A7D150L39d70W6 |

150 |

1000 |

70 |

6T |

|

A7D150L43d70W6 |

150 |

1100 |

70 |

6T |

|

A7D150L52d70W6 |

150 |

1320 |

70 |

6T |

|

A7D150L39d80W6 |

150 |

1000 |

80 |

6T |

|

A7D150L43d80W6 |

150 |

1100 |

80 |

6T |

|

A7D150L52d80W6 |

150 |

1320 |

80 |

6T |

|

A7D150L39d70W8 |

150 |

1000 |

70 |

8T |

|

A7D150L43d70W8 |

150 |

1100 |

70 |

8T |

|

A7D150L52d70W8 |

150 |

1320 |

70 |

8T |

|

A7D150L39d80W8 |

150 |

1000 |

80 |

8T |

|

A7D150L43d80W8 |

150 |

1100 |

80 |

8T |

|

A7D150L52d80W8 |

150 |

1320 |

80 |

8T |

|

A7D180L36d70W8 |

180 |

910 |

70 |

8T |

|

A7D180L39d70W8 |

180 |

1000 |

70 |

8T |

|

A7D180L43d70W8 |

180 |

1100 |

70 |

8T |

|

A7D180L52d70W8 |

180 |

1320 |

70 |

8T |

|

A7D180L36d70W10 |

180 |

910 |

70 |

10T |

|

A7D180L39d70W10 |

180 |

1000 |

70 |

10T |

|

A7D180L43d70W10 |

180 |

1100 |

70 |

10T |

|

A7D180L52d70W10 |

180 |

1320 |

70 |

10T |

|

A7D180L36d80W8 |

180 |

910 |

80 |

8T |

|

A7D180L39d80W8 |

180 |

1000 |

80 |

8T |

|

A7D180L43d80W8 |

180 |

1100 |

80 |

8T |

|

A7D180L52d80W8 |

180 |

1320 |

80 |

8T |

|

A7D180L36d80W10 |

180 |

910 |

80 |

10T |

|

A7D180L39d80W10 |

180 |

1000 |

80 |

10T |

|

A7D180L43d80W10 |

180 |

1100 |

80 |

10T |

|

A7D180L52d80W10 |

180 |

1320 |

80 |

10T |

|

A7D200L36d100W10 |

200 |

910 |

100 |

10T |

|

A7D200L39d100W10 |

200 |

1000 |

100 |

10T |

|

A7D200L43d100W10 |

200 |

1100 |

100 |

10T |

|

A7D200L52d100W10 |

200 |

1320 |

100 |

10T |

|

A7D200L36d100W12 |

200 |

910 |

100 |

12T |

|

A7D200L39d100W12 |

200 |

1000 |

100 |

12T |

|

A7D200L43d100W12 |

200 |

1100 |

100 |

12T |

|

A7D200L52d100W12 |

200 |

1320 |

100 |

12T |

Specification

Specification for Spiral Cutter Head (15 x 15 x 2.5° mm, 37 bevel)

|

Model |

Diameter (mm) |

Length (mm) |

Bore (mm) |

Wing |

|---|---|---|---|---|

|

HA7D125L 2d40W6 |

125 |

50 |

40 |

6T |

|

HA7D125L 3d40W6 |

125 |

75 |

40 |

6T |

|

HA7D125L 4d40W6 |

125 |

100 |

40 |

6T |

|

HA7D125L 5d40W6 |

125 |

125 |

40 |

6T |

|

HA7D125L 6d40W6 |

125 |

155 |

40 |

6T |

|

HA7D125L 7d40W6 |

125 |

180 |

40 |

6T |

|

HA7D125L 8d40W6 |

125 |

205 |

40 |

6T |

|

HA7D125L 9d40W6 |

125 |

230 |

40 |

6T |

|

HA7D125L10d40W6 |

125 |

255 |

40 |

6T |

|

HA7D125L11d40W6 |

125 |

280 |

40 |

6T |

|

HA7D125L12d40W6 |

125 |

305 |

40 |

6T |

|

HA7D125L 2d46W6 |

125 |

50 |

46 |

6T |

|

HA7D125L 3d46W6 |

125 |

75 |

46 |

6T |

|

HA7D125L 4d46W6 |

125 |

100 |

46 |

6T |

|

HA7D125L 5d46W6 |

125 |

125 |

46 |

6T |

|

HA7D125L 6d46W6 |

125 |

155 |

46 |

6T |

|

HA7D125L 7d46W6 |

125 |

180 |

46 |

6T |

|

HA7D125L 8d46W6 |

125 |

205 |

46 |

6T |

|

HA7D125L 9d46W6 |

125 |

230 |

46 |

6T |

|

HA7D125L10d46W6 |

125 |

255 |

46 |

6T |

|

HA7D125L11d46W6 |

125 |

280 |

46 |

6T |

|

HA7D125L12d46W6 |

125 |

305 |

46 |

6T |

|

HA7D125L 2d50W6 |

125 |

50 |

50 |

6T |

|

HA7D125L 3d50W6 |

125 |

75 |

50 |

6T |

|

HA7D125L 4d50W6 |

125 |

100 |

50 |

6T |

|

HA7D125L 5d50W6 |

125 |

125 |

50 |

6T |

|

HA7D125L 6d50W6 |

125 |

155 |

50 |

6T |

|

HA7D125L 7d50W6 |

125 |

180 |

50 |

6T |

|

HA7D125L 8d50W6 |

125 |

205 |

50 |

6T |

|

HA7D125L 9d50W6 |

125 |

230 |

50 |

6T |

|

HA7D125L10d50W6 |

125 |

255 |

50 |

6T |

|

HA7D125L11d50W6 |

125 |

280 |

50 |

6T |

|

HA7D125L12d50W6 |

125 |

305 |

50 |

6T |

|

HA7D125L 2d40W8 |

125 |

50 |

40 |

8T |

|

HA7D125L 3d40W8 |

125 |

75 |

40 |

8T |

|

HA7D125L 4d40W8 |

125 |

100 |

40 |

8T |

|

HA7D125L 5d40W8 |

125 |

125 |

40 |

8T |

|

HA7D125L 6d40W8 |

125 |

155 |

40 |

8T |

|

HA7D125L 7d40W8 |

125 |

180 |

40 |

8T |

|

HA7D125L 8d40W8 |

125 |

205 |

40 |

8T |

|

HA7D125L 9d40W8 |

125 |

230 |

40 |

8T |

|

HA7D125L10d40W8 |

125 |

255 |

40 |

8T |

|

HA7D125L11d40W8 |

125 |

280 |

40 |

8T |

|

HA7D125L12d40W8 |

125 |

305 |

40 |

8T |

|

HA7D125L 2d46W8 |

125 |

50 |

46 |

8T |

|

HA7D125L 3d46W8 |

125 |

75 |

46 |

8T |

|

HA7D125L 4d46W8 |

125 |

100 |

46 |

8T |

|

HA7D125L 5d46W8 |

125 |

125 |

46 |

8T |

|

HA7D125L 6d46W8 |

125 |

155 |

46 |

8T |

|

HA7D125L 7d46W8 |

125 |

180 |

46 |

8T |

|

HA7D125L 8d46W8 |

125 |

205 |

46 |

8T |

|

HA7D125L 9d46W8 |

125 |

230 |

46 |

8T |

|

HA7D125L10d46W8 |

125 |

255 |

46 |

8T |

|

HA7D125L11d46W8 |

125 |

280 |

46 |

8T |

|

HA7D125L12d46W8 |

125 |

305 |

46 |

8T |

|

HA7D125L 2d50W8 |

125 |

50 |

50 |

8T |

|

HA7D125L 3d50W8 |

125 |

75 |

50 |

8T |

|

HA7D125L 4d50W8 |

125 |

100 |

50 |

8T |

|

HA7D125L 5d50W8 |

125 |

125 |

50 |

8T |

|

HA7D125L 6d50W8 |

125 |

155 |

50 |

8T |

|

HA7D125L 7d50W8 |

125 |

180 |

50 |

8T |

|

HA7D125L 8d50W8 |

125 |

205 |

50 |

8T |

|

HA7D125L 9d50W8 |

125 |

230 |

50 |

8T |

|

HA7D125L10d50W8 |

125 |

255 |

50 |

8T |

|

HA7D125L11d50W8 |

125 |

280 |

50 |

8T |

|

HA7D125L12d50W8 |

125 |

305 |

50 |

8T |

|

HA7D125L17d50W6 |

125 |

450 |

50 |

6T |

|

HA7D125L18d50W6 |

125 |

460 |

50 |

6T |

|

HA7D125L17d50W8 |

125 |

450 |

50 |

8T |

|

HA7D125L18d50W8 |

125 |

460 |

50 |

8T |

|

HA7D150L20d50W6 |

150 |

500 |

50 |

6T |

|

HA7D150L20d50W6 |

150 |

610 |

50 |

6T |

|

HA7D150L20d60W6 |

150 |

500 |

60 |

6T |

|

HA7D150L20d60W6 |

150 |

610 |

60 |

6T |

|

HA7D150L20d70W6 |

150 |

500 |

70 |

6T |

|

HA7D150L20d70W6 |

150 |

610 |

70 |

6T |

|

HA7D150L20d50W8 |

150 |

500 |

50 |

8T |

|

HA7D150L20d50W8 |

150 |

610 |

50 |

8T |

|

HA7D150L20d60W8 |

150 |

500 |

60 |

8T |

|

HA7D150L20d60W8 |

150 |

610 |

60 |

8T |

|

HA7D150L20d70W8 |

150 |

500 |

70 |

8T |

|

HA7D150L20d70W8 |

150 |

610 |

70 |

8T |

|

HA7D150L36d70W6 |

150 |

910 |

70 |

6T |

|

HA7D150L36d80W6 |

150 |

910 |

80 |

6T |

|

HA7D150L36d70W8 |

150 |

910 |

70 |

8T |

|

HA7D150L36d80W8 |

150 |

910 |

80 |

8T |

|

HA7D150L39d70W6 |

150 |

1000 |

70 |

6T |

|

HA7D150L43d70W6 |

150 |

1100 |

70 |

6T |

|

HA7D150L52d70W6 |

150 |

1320 |

70 |

6T |

|

HA7D150L39d80W6 |

150 |

1000 |

80 |

6T |

|

HA7D150L43d80W6 |

150 |

1100 |

80 |

6T |

|

HA7D150L52d80W6 |

150 |

1320 |

80 |

6T |

|

HA7D150L39d70W8 |

150 |

1000 |

70 |

8T |

|

HA7D150L43d70W8 |

150 |

1100 |

70 |

8T |

|

HA7D150L52d70W8 |

150 |

1320 |

70 |

8T |

|

HA7D150L39d80W8 |

150 |

1000 |

80 |

8T |

|

HA7D150L43d80W8 |

150 |

1100 |

80 |

8T |

|

HA7D150L52d80W8 |

150 |

1320 |

80 |

8T |

|

HA7D180L36d70W8 |

180 |

910 |

70 |

8T |

|

HA7D180L39d70W8 |

180 |

1000 |

70 |

8T |

|

HA7D180L43d70W8 |

180 |

1100 |

70 |

8T |

|

HA7D180L52d70W8 |

180 |

1320 |

70 |

8T |

|

HA7D180L36d70W10 |

180 |

910 |

70 |

10T |

|

HA7D180L39d70W10 |

180 |

1000 |

70 |

10T |

|

HA7D180L43d70W10 |

180 |

1100 |

70 |

10T |

|

HA7D180L52d70W10 |

180 |

1320 |

70 |

10T |

|

HA7D180L36d80W8 |

180 |

910 |

80 |

8T |

|

HA7D180L39d80W8 |

180 |

1000 |

80 |

8T |

|

HA7D180L43d80W8 |

180 |

1100 |

80 |

8T |

|

HA7D180L52d80W8 |

180 |

1320 |

80 |

8T |

|

HA7D180L36d80W10 |

180 |

910 |

80 |

10T |

|

HA7D180L39d80W10 |

180 |

1000 |

80 |

10T |

|

HA7D180L43d80W10 |

180 |

1100 |

80 |

10T |

|

HA7D180L52d80W10 |

180 |

1320 |

80 |

10T |

|

HA7D200L36d100W10 |

200 |

910 |

100 |

10T |

|

HA7D200L39d100W10 |

200 |

1000 |

100 |

10T |

|

HA7D200L43d100W10 |

200 |

1100 |

100 |

10T |

|

HA7D200L52d100W10 |

200 |

1320 |

100 |

10T |

|

HA7D200L36d100W12 |

200 |

910 |

100 |

12T |

|

HA7D200L39d100W12 |

200 |

1000 |

100 |

12T |

|

HA7D200L43d100W12 |

200 |

1100 |

100 |

12T |

|

HA7D200L52d100W12 |

200 |

1320 |

100 |

12T |

Insert knife

Depending on workpiece’s material, LR Tool provide 2 kinds of material insert knife. First is KCR08 for normal hardwood. Next is the SMG02, suitable for extremely hard or man‐made material like plywood or MDF.

|

Size |

Material |

|---|---|

|

14 mm x 14 mm x 2.0 mm (30-degree bevel) |

Tungsten Carbide (kcr08) |

|

14 mm x 14 mm x 2.0 mm (30-degree bevel) |

Tungsten Carbide (smg02) |

|

15 mm x 15 mm x 2.5 mm (37-degree bevel) |

Tungsten Carbide (kcr08) |

|

15 mm x 15 mm x 2.5 mm (37-degree bevel) |

Tungsten Carbide (smg02) |

Accessory